♥️ mfa photography 2019-2021, rhode island school of design, address: 2 college st, providence, ri 02903. fletcher building studio 607 A/B. bfa photography 2014-2016, california state university of long beach. artist and researcher born in riverside, ca, 1989.

♥️ area of interest: media theory/ecology, popular culture, critical animal studies, cognitive science, child development, video game theory, phenomenology, neuromarketing, animal agriculture, psychology, and working with the youth.

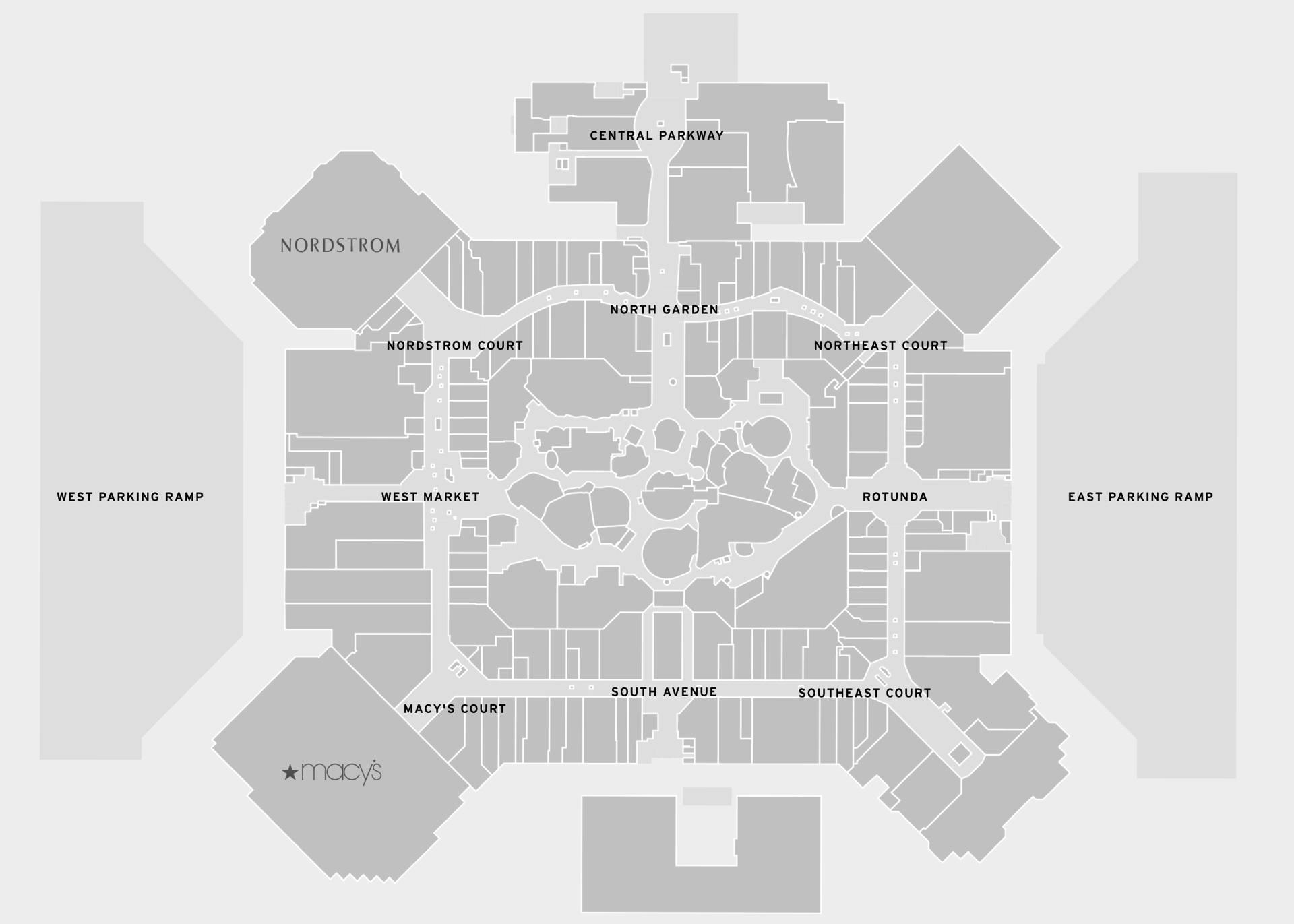

Image

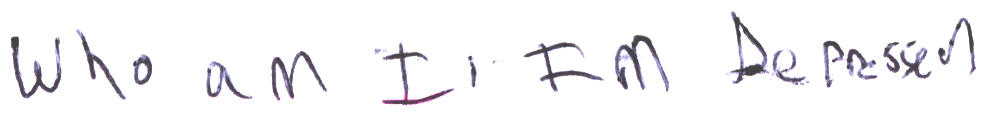

▲ handwriting by a 10-year-old when I asked, "How would you feel if all of social media disappeared tomorrow?" 2020.

♥️ "There could not have been a safer bet when it began in 1969 than that 'Sesame Street' would be embraced by children, parents, and educators. Children loved it because they were raised on television commercials, which they intuitively knew were the most carefully crafted entertainments on television." — Neil Postman, Teaching as an Amusing Activity, 1985.

♥️ "In the end, the human, like the environment, is redesigned into a form that fits the needs of the commercial format." — Jerry Mander, The Colonization of Experience, 1978.

.・゜゜*:・゚✧*:・゜゜・ .・゜゜・*:・゚✧*:・゜゜・..・゜゜・*:・゚✧*:・゜゜・.・゜゜*:・゚✧*:・゜゜.・゜゜*:・゚✧*:゜゜・ .・゜゜・..

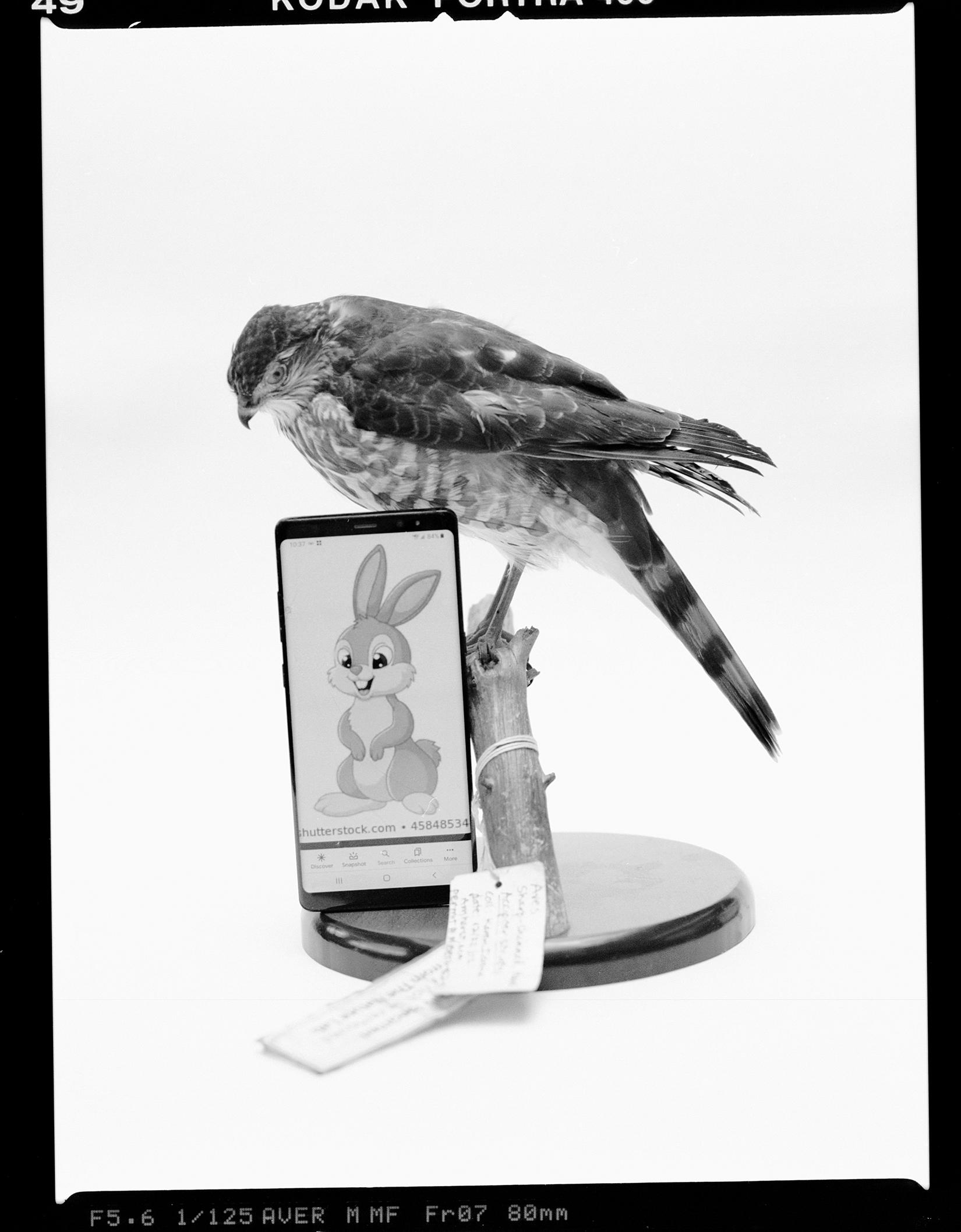

Image

"They use force, to make you do, what the deciders, have decided you must do." — rage against the machine

"Please don't stop the music. Please don't stop the music. Please don't stop the music. Please don't stop the music. Please don't stop the music. Please don't stop the music." — rihanna

"I'm loose. And everybody knows I get off the chain. Baby it's the truth, it's the truth. I'm like Inception. I play with your brain." — j.lo ft. pitbull

▾ YouTube Screenshot, 2020 (Video No Longer Available)

Image

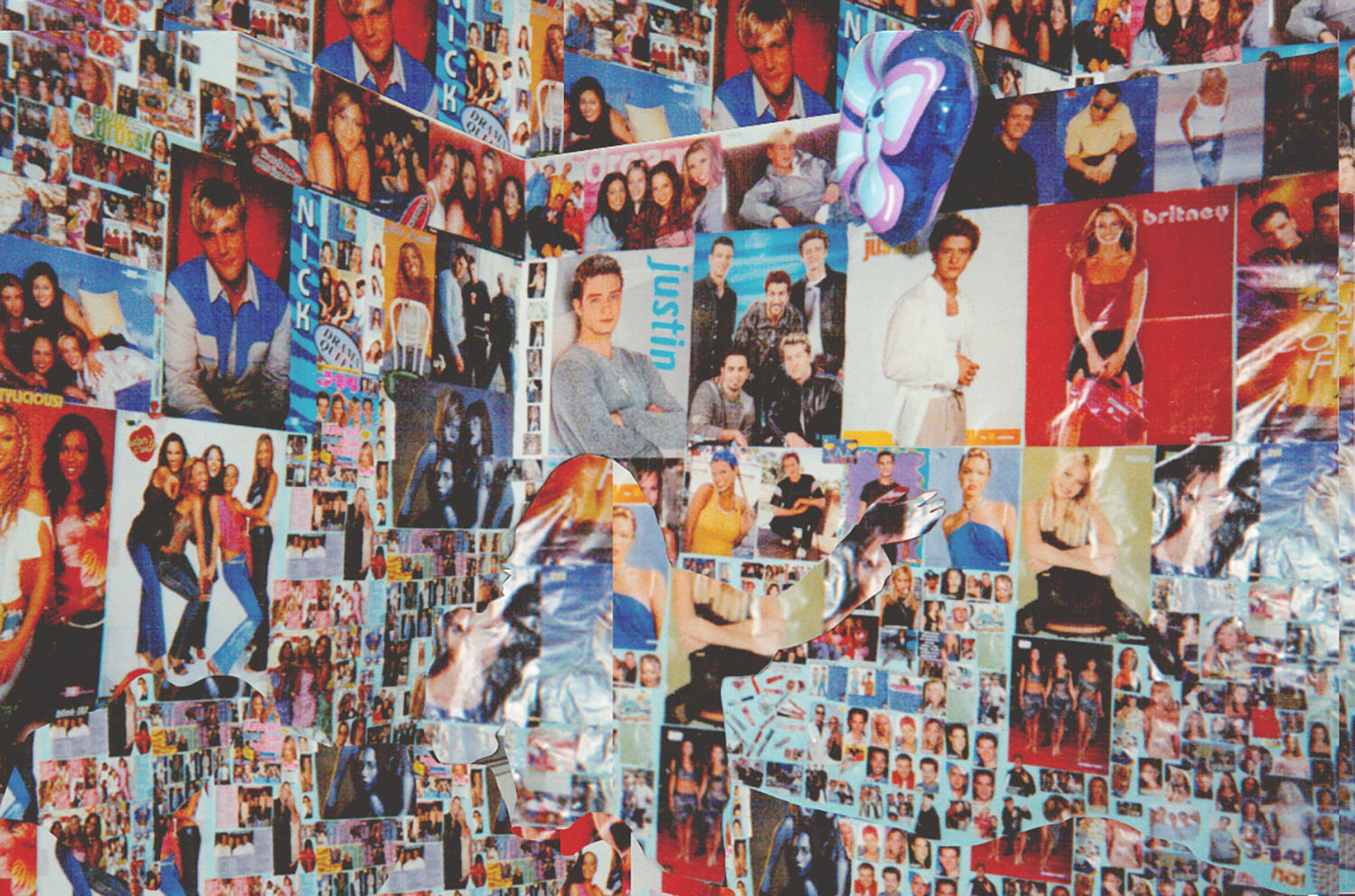

▾ Welcome to My Room! (cloaked self), 2000/2020 — as I consumed images, images consumed me.

Image

▾ First Day of Spring (self in pink dress), 1995 — gradual accumulation towards an artificial way of "knowing"

Image

▾ Farmer John Slaughterhouse Mural, Vernon, California (Screenshot Google Maps)

Image

▾ Steffanie A. Padilla, Notes on Vision, 2021

Image

“... [in photography] the delayed revelation is that images are always false. Artificial snapshots of moments that have never existed as singularities, forced from the multidimensional flow of time itself. Unreliable documents; composites of camera and attention. They are artifacts not of the world and of experience, but of the recording process—which, as a false mechanism, can never approach reality itself. It is only when these processes of capture and storage are reified in technology like Photoshop or Google Assistant that we are able to perceive their falsity, their alienation from reality. History is not something that can be reliably narrativized; and neither can the future.”

— James Bridle, New Dark Age: Technology and the End of the Future, 2018.

▾ Steffanie A. Padilla, árbol-tree, México

Image

Image

▲ WOW, 2021

Clay, 12” x 10” inches

Grad Show 2021 Thesis Installation—Steffanie A. Padilla

Image

▲ Brushed Eye, 2021

archival inkjet print, 7.75” x 9.75” inches

Grad Show 2021 Thesis Installation—Steffanie A. Padilla

▾ Steffanie A. Padilla, Captivity, 2018

Image

▾ Steffanie A. Padilla, Artifacts #123, 2020

Image

“Give them pain and fear and then help them eliminate it.”

— Neuromarketing strategy that hits the subconscious

“Most people don’t try to parse cuteness. Like pornography, we know it when we see it. With a bit of examination, however, cuteness has easily quantifiable aesthetics. Take a moment to picture whatever you find cute—puppies, kittens, cartoon characters, or your own children. Cuteness is the type of attractiveness associated with youth, so your ‘cute’ objects no doubt have youthful traits. Infants of most species have a small body with a disproportionately large head, big eyes, small nose, chubby limbs, and clumsy coordination. Youthful behavior includes playfulness, affection, helplessness, and a need to be nurtured. A few characteristics such as dimples and baby talk are unique to humans, but most are common across species. Evolutionary biologists view ‘cuteness’ as simply the mechanism by which infantile features trigger nurturing in adults—a crucial adaptation for survival. Scientific studies find that definitions of cuteness are similar across cultures. So are our responses.”

—Deirdre Barrett, Supernormal Stimuli: How Primal Urges Overran Their Evolutionary Purpose, 2010.

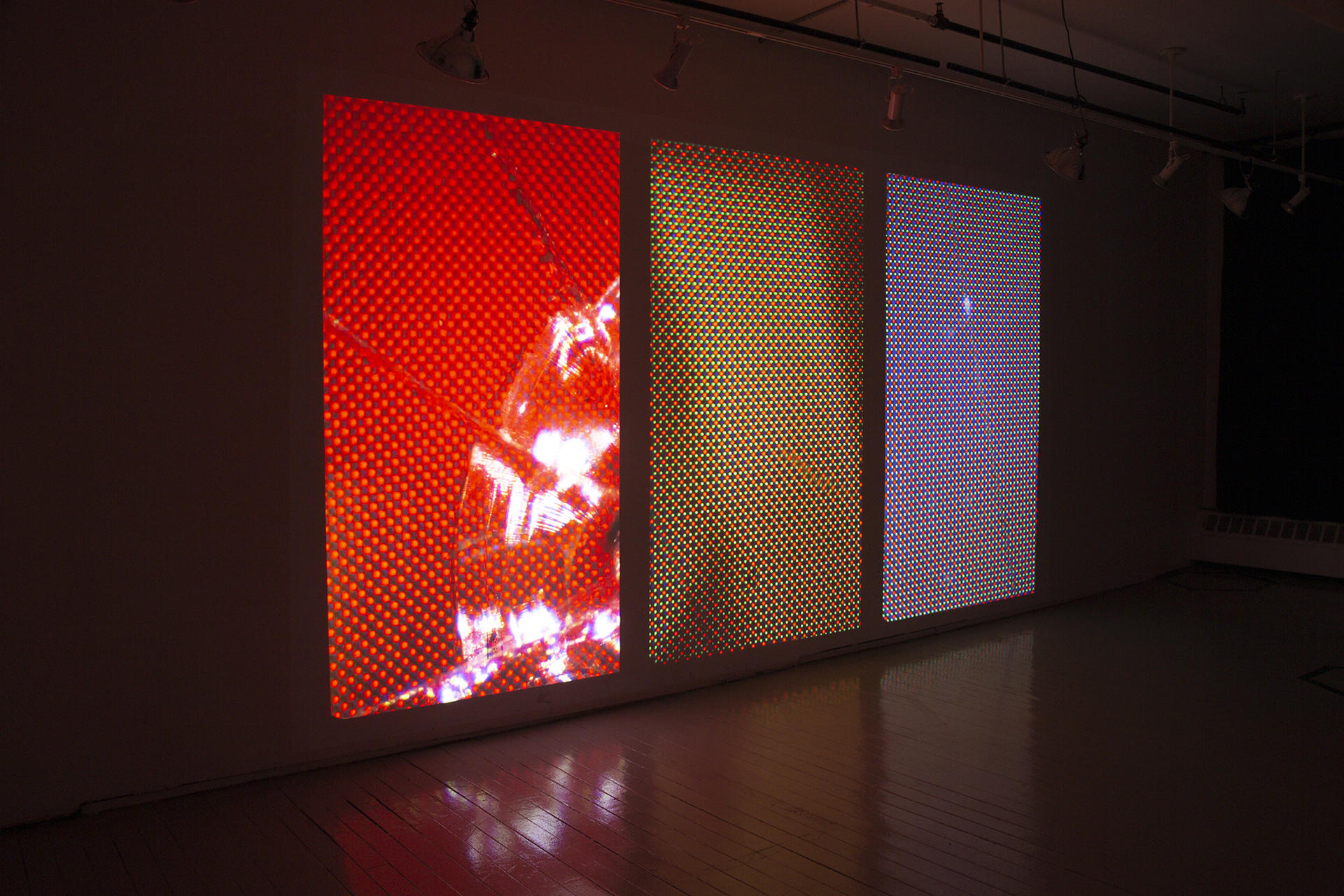

▾ Steffanie A. Padilla, (video) This Is All for You, color, sound — TikTok videos viewed under a microscope (Nature Lab) with cracked phone screen, 2021

Image

“The typical newborn brain is 333 grams and in the first two years of life, it actually triples in size. It is an extraordinary period of brain growth, unparalleled over the life course. We're born with about 2,500 synapses and by age-3 we have 15,000. And then over time, those connections are actually pruned in response to the external stimulation. The external world that we live in.”

— Dimitri Christakis on Media and Children, 2011.

▾ Steffanie A. Padilla, Imma Bee, left/unaltered—right/altered, dead bee found in my home and viewed under microscope.

Image

Image

Image

Image

Image

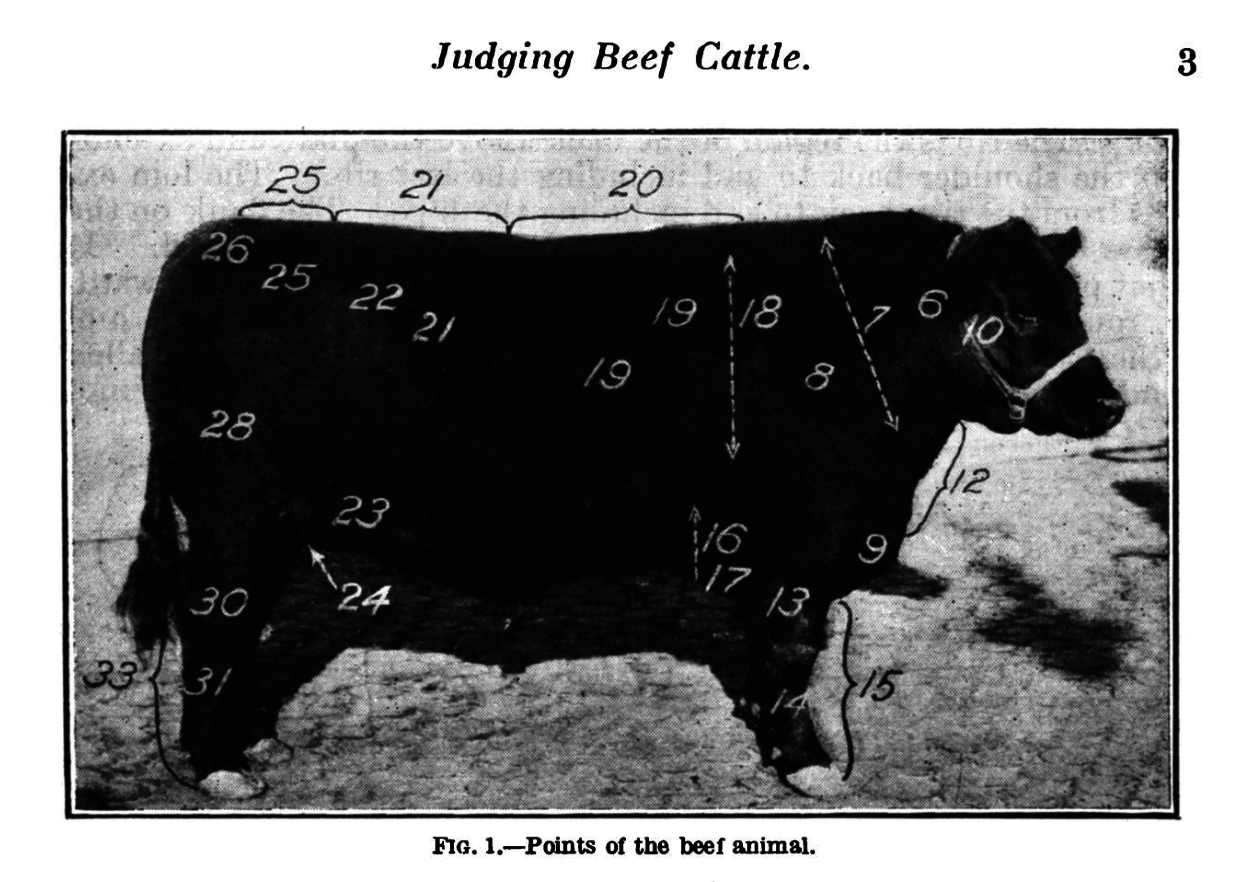

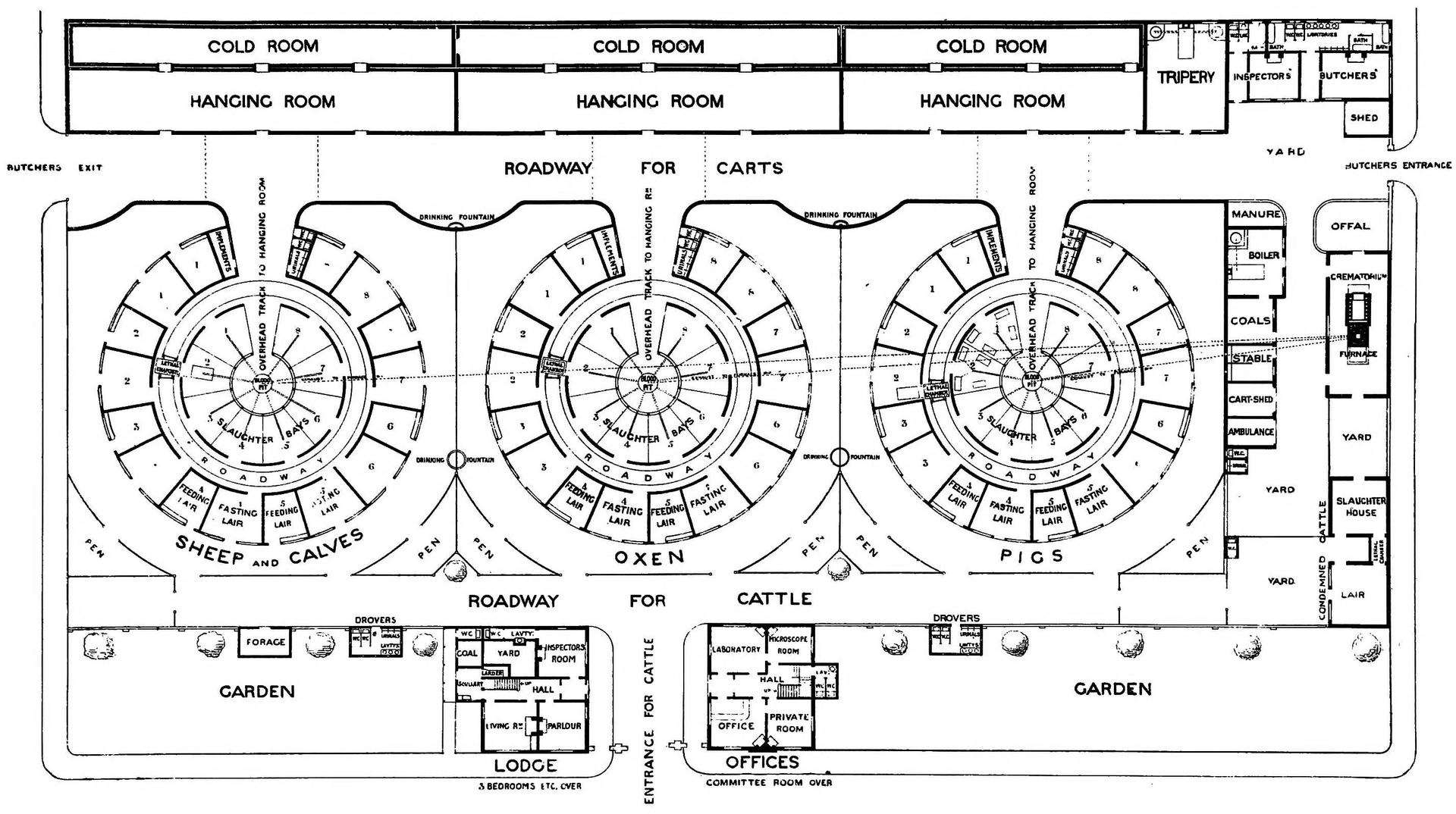

121 Repetitive Jobs in an Industrialized Slaughterhouse

—Division of Labor on the Kill Floor—

Every Twelve Seconds: Industrialized Slaughter and the Politics of Sight by Timothy Pachirat

1. Cattle Driver: Works in pens and squeeze pen; uses electric prods, paddles, whips, and voice to drive cattle into serpentine (paths).

2. Serpentine Cattle Driver: Works in serpentine; uses electric prods, paddles, whips, and voice to drive cattle up serpentine and into knocking box. Also responsible for marking lot cow.

3. Knocker: Operates the knocking box. Uses air gun to drive captive-steel bolt into foreheads of cattle while they are suspended on center track and restrained by side walls.

4. Shackler: Shackles rear left hind let of cattle with chain suspended from overhead rail; can shackle either before or after knocked cattle fall onto green conveyor belt from which they are lifted up by the chain.

5. Indexer/Hand Knocker: Uses long metal pole to space cattle between “dogs” on overhead rail; uses cap-gun hand knocker to shoot cattle that show signs of sentience after passing through knocking box.

6. Ear-tag Recorder: Uses paper forms to record ear-tag number and color of each cow; also keeps track of lot numbers.

7. Presticker: Uses hand knife to make incision along length of the cow’s neck, giving the sticker access to jugular vein and carotid arteries. Must make take care not to be kicked in face, arms, chest, neck, or abdominal area by cows that are reflexively kicking, or kicking because they have not been knocked completely unconscious.

8. Sticker: Reaches into the incision made by the presticker and uses hand knife to cut jugular veins and carotid arteries of cow.

9. Tail Ripper: Uses hydraulic scissor-type knife to cut off bottom third of tail; disposes of the down a chute; uses hand knife to make an incision from the anus to the teat or penis area.

10. First Legger: Uses hand knife to cut hide off rear right leg, opening hide to expose flesh underneath.

11. Bung Capper: Uses hand knife to cut around anus.

12. First Hock Cutter: Uses large hydraulic shears to sever right hind hoof about six to ten inches from end and deposits hoof in chute; uses hand knife to poke hole between tendon and lower leg bone.

13. Belly Ripper: Uses hand knife to make incision down length of cow, starting from udder or penis area where the tail ripper left off and continuing to about mid-chest level.

14. First Codder: Uses air knife to skin inside thigh of right hind leg, picking up at point where first legger left off.

15. First Butter: Uses air knife to separate hide from flesh around anus area.

16. First Hock Vaccum: Sticks enormous metal air vacuum over first hock (hind right leg, now clipped by first hock cutter) and holds it there for approximately seven seconds to clean area of fecal material and hair.

17. First Hang Off: Inserts metal hook attached to metal wheel pushed by “dogs” on separate overhead rail system into the hock hole created by the first hock cutter; guides/lifts the wheel onto the main rail track.

18. Trimmer: Uses handheld trimming knife to clear area between right hind leg and anus of fecal matter and hair; position exists primarily in winter months when there is more fecal matter on cattle.

19. Unshackler/LowRaider: Uses hands to release shackle as a machine called a low raider lowers left hind leg of cow. Cow now hangs from hook threaded through hole in leg created by the first hock cutter.

20. Second Legger: Uses hand knife to skin left hind leg, exactly as first legger has done for right hind leg.

21. Second Hock Cutter: Uses hock cutter to cut approximately six to eight inches of left hind leg off and then uses hand knife to poke hole between tendon and bone on left hind leg, exactly as first hock cutter has done for right hind leg.

22. Second Codder: Uses air knife to skin inside thigh of left hind leg, picking up where second legger left off.

23. Second Butter: Uses air knife to separate hide from flesh around anus area.

24. Second Hock: Vacuum performs job identical to first hock vacuum, except on left hind hock instead of right hind hock.

25. Second Hang Off: Takes hook attached to trolly and threads it through hole in left hind hock created by second hock cutter and then guides/pulls trolley wheel onto overhead rail. Cow is now suspended from two overhead troll eyes, one hooked through each of its hind legs.

26. Trimmer: Trims area between anus and left hock for fecal matter and hair; position exists primarily in winter months when there is more fecal matter on cattle.

27. Lower Belly Ripper: Uses hand knife hook to open lower half of pattern in hide, picking up where upper belly ripper left off.

28. Rim Over: Uses air knife to skin from shoulder area of cattle, on both left and right sides.

29. Right Flanker: Uses air knife to skin right flank as fair back as possible to prepare hide for side puller.

30. Tai Bagger/Breed Stamper: Places plastic bag over cow’s tail, then fastens the bag on tail with rubber hand to prevent feces from flying off tail onto rest of cow when the tail puller pulls hide off cow; stamps cattle according to breed — “A” for Angus, “H” for Hereford and “C” for mixed Hereford and Angus — placing one mark on each side of rump.

31. Bung Stuffer: Wads up large sheet of thin paper and stuffs it deep into cow’s annus to prevent feces from flying out of anus when the tail ripper pulls hide up off tail.

32. Right Rumper: Uses air knife to skin hide on right rump as far back as possible..

33. Left Rumper: Uses air knife to skin hide on left rump as far as possible.

34. Left Flanker: Uses air knife to skin left flank as far back as possible, to prepare hie for side puller.

35. Paper Liner: Places thin pice of large rectangular paper on inside of each fold of flank hide to lessen likelihood of feces flying off outside and contaminating flesh during side puller operations.

36. Ear/Nose Cutter: Uses hand knife to slice off left ear and left nostril of cow. Stands on floor and wears full face shield to protect against copious amounts of blood.

37. Ear/Nose/Horn Cutter: Uses hand knife to slice off right ear and right nostril of cow. On any cows with horns, uses hydraulic shears and three and a half foot-long cleaver to sever horns. Stands on floor and wear full face shield to protect against copious amounts of blood.

38. Bungee-Cord Attacher: Uses hands to place bungee cord attached to metal clamps on hide, with paper between clamps. One end of bungee cord goes on trailing hide of one away from carcass to reduce amount of fecal material that is transferred to carcass by contact with hide.

39. Third Hock Cutter: Uses hydraulic shears to sever from left and right hoofs of cow, approximately five to eight inches up from bottom of each hoof. Severed hoofs are placed on conveyor that leads through hole in wall to foot cocking room.

40. Side Puller Operator: Operates large clamps attached to hydraulic arms by inserting flank hide into clamps, shutting clamps, then activating retracting on hydraulic arms to rip back hide and expose cow’s front and belly.

40a. Whizard Knife Belly Trimmer: Uses circular Whizard knife to trim excess fat off belly area.

41. Backer: Uses air knives to cut pocket between hide and skin in middle back area of cattle while standing on moving conveyor. Backers must synchronize movements and work in tandem.

42. Tail Puller Operator: Uses hand to slide leading edge of back hide of each cow into long metal bar called banana bar. Once bar has slid all the way through the pocket created by the backer, the hydraulic-powered banana bar is activated and shoots upward, ripping hide off upper back area of cow, and ripping tail hide, including plastic bag on tail, off. At this point upper hide now hangs over lower half of cow, creating effect of white-fleshed upper body and lower body draped with hide.

43. Bungee-Cord Remover: Removes bungee cords and flank paper and places them on rack to be returned to bungee-cord attacher.

44. Trimmer: Uses hand knife to trim rump, anus, and tail area for fecal matter and hair; position exists primarily in winter when there is more fecal matter on cattle.

45. Pizzle Remover: Uses hand knife to sever penis or udder.

46. Neck Opener: Makes incision in hide at neck area, below incision made by first sticker.

47. Down Puller Operator: Uses hook to insert reading edge of draped hide into cylindrical metal spinner. Once inserted, worker uses levers to operate spinner, which rolls hide up as it spins, ripping hide off bottom half of carcass, including head. Once hide has been stripped completely from cow, spin is reversed and hide falls into collection chute. At this point, hide is completely removed from cow, and cow passes through wall which demarcates “clean” from “dirty”.

48. Dentition Worker: Uses hooks or fingers to open each cow’s mouth and examine its teeth in order to determine whether it is over or under thirty months of age. If more than thirty months, cattle are at higher risk for BSE and dentition worker attaches red “30 month” tags to left side of cow’s forehead and left shoulder area and plugs brain hole created by knocker with cork.

49. Dentition Assistant: Records number of each thirty-month cow on sheet of paper and attaches yellow tag to weasand from thirty-month cattle.

50. Trimmer: Uses hand knife to trim neck and back area of cattle for fecal material.

51. Steam-Vacuum Worker: Uses handheld metal vacuum nozzles to suction off any remaining fecal material or hair before cow enters prewash cabinet. Some workers vacuum inside first and second hock, others outside first and second hock, and others the back and gut areas.

52. Fourth Hock Cutter: Uses hock cutter to further trim two bottom hocks/shanks by about one or two inches to rid shanks of any contamination that might have occurred at down puller. Disposes of shank pieces in gray barrel.

53. Ear Cutter: Uses hand knife to cut ears completely off cow’s head. Discards ears in gray barrel.

54. Tail Cutter/Prewash Operator: Uses hand knife to trim skinned tail. Also, turns off prewash cabinet when a thirty-month cow passes through. Prewash cabinet sprays liquid solution of lactic acid on cattle to reduce micro-bacterial contamination.

55. Brisket Marker: Uses hand knife to make incision in brisket, or from chest, area of cow in preparation for brisket saw operator.

56. Brisket Saw Operator: Uses electric saw to follow incision made by brisket marker and cut through brisket of cow, allowing access to gullet clearer.

57. Head Dropper: Uses hand knife to cut through neck, leaving head dangling by windpipe.

58. Head Severer/Hanger: Takes hook from head line, sinks it into base of skull, and severs windpipe so that head leaves body of cow and swings down onto head-line hook. Marks each head with tag corresponding to number of body it came from.

59. Gullet Clearer: Uses hand knife to reach into neck of cow and pull out gullet.

60. Pregutter/Bladder Remover: Uses hand knife to make incision in udder or penis area of cow, then reaches in with hand and knife and cuts out bladder. After puncturing bladder, discards it down narrow chute.

61. Head Flusher: Inserts double-headed nozzle into back of each head and sprays powerful stream of water through head to wash tongue and cheeks of any ingesta.

62. Tongue Clipper and Washer: Uses hydraulic shears to cut tongue bones, then uses hand knife to pull tongue out of head. Severs tongue and hangs it on hook next to head.

63. Tongue Washer: Sprays tongues with water to clear them.

64. Pre-USDA Head Trimmer: Uses hand knife to trim heads of any contamination before they reach USDA headline inspectors.

65. Post-USDA Head Trimmer: Uses hand knife to trim head in accordance with USDA inspector directives.

66. Gland Trimmer: Removes heads from head-line hooks and uses hand knife to trim head glands before putting heads on chiseler table.

67. Tongue Trimmer: Removes tongues from head-life hooks and places them on trimming stand. Uses hand knife to trim bottom portion of tongue.

68. Head Chiseler: Uses pointed hydraulic metal chiseler operated by food levers to scrape flesh off jaw bone, then uses hydraulic metal bar, also activated by foot lever, to force jaw from skull. Sends both jaw and skull down small ramp to head table conveyor.

69. Head, Cheek, and Lip Meat Trimmer: Pulls jaws and skulls off head table conveyor and uses hand and/or Whizard knife to scrape head and cheek meat and to cut inner lips from skull and jaw. Uses hook to toss meat into one of three chutes: head meat chute, cheek meat chute, or lip meat chute.

70. Head, Check, and Lip Meat Boxer: Operates trapdoors to head, cheek, and lip meat chutes in order to pack meat into boxes. Weighs boxes, uses electronic scale, puts cover on boxes, and places boxes on offal conveyor.

71. Bung Dropper: Uses hand knife to cut around anus and cut large intestine away from anus. Pulls large intestine out of anus, caps it with plastic bag, then stuffs it back into anus to prevent feces from leaving large intestine when alimentary system is gutted and dropped onto viscera table.

72. Weasand Rodder: Uses hands to push a long rod into the windpipe of cow and pull out the weasand by separating it from windpipe. Clips end of weasand with serrated plastic clip.

73. Tail Harvester: Uses knife to sever tail and hang it on offal life.

74. Gutter: Steps onto removing viscera table and uses hand knife to slit cow open, connecting incisions made by pregutter and brisket saw operator. Reaches into incision with hand knife and severs heart, lungs, liver, pancreas, and gallbladder and drops these, along with stomach, small intestine, and large intestine, onto viscera table, where they are inspected by USDA inspectors. Widely considered one of the most physically challenging and skilled jobs on the kill floor.

75. Liver Harvester: Uses hand knife to separate liver from gallbladder; cuts excess fat from liver and cuts gallbladder before dropping skin of gallbladder down gallbladder chute.

76. Weasand Remover: Uses hand knife and pulling motion to split weasand; severs weasand from windpipe and throws it back on viscera table.

77. Offal Hanger: Uses hands to hang hearts and weasand on offal line and livers on liver line; throws lungs, pancreases, windpipes, and any fetuses down pet-food cute.

78. Paunch Separator: Uses hand knife to separate paunch from intestines.

79. Heart Trimmer: Uses hand knife to open and trim hearts.

80. Pet-Food Trimmer: Uses hand knife to trim pet-food parts such as lungs, pancreas, and windpipe.

81. Paunch Puller: Uses handheld hooks to pull paunches and intestines off large viscera table onto small viscera table leading to gut room.

82. Trimmer: Uses hand knife to trim front shoulder area of cow for fecal material and hair.

83. Split Saw Operator: Stands on movable platform and holds large bandsaw. Uses foot to operate lever that mechanically raises and lowers platform while using bandsaw to split the cow in half through backbone, starting from anus down to neck.

84. Spinal Cord Remover: Uses vacuum and long tubular rod to remove spongy spinal cord from split cow.

85. Kidney Dropper: Uses hook to pull kidney down so that it hangs visibly in half-carcass.

86. High Trimmer: Uses hand knife and hook to trim hind hocks and rump area of cow prior to USDA trim-line inspection.

87. Mid-Trimmer: Uses hand knife and hook to trim middle area of cow prior to USDA trim-line inspection.

88. Post-USDA Mid Trimmer: Uses hand knife and hook to correct any problems noted in middle area of cow by USDA mid-level trim-rail inspector.

89. Post-USDA High Trimmer: Uses hand knife and hook to correct any problems noted in high area of cow by the USDA high-level trim-rail operator.

90. Kidney Remover: Uses hand knife and hook to sever kidneys and throw them into gray barrel.

91. Hot-Scale Operator: Uses computer to weigh and print weight information on each cow. Uses pin to tag half-carcasses with slaughter number, lot number, sex, breed, and post slaughter and evisceration weight.

92. Outrail Trimmer: Uses hand knife, hook, and electric well saw to trim cattle that failed USDA trim-rail inspection.

93. Steam-Vacuum Worker: Uses metal vacuum nozzle connected to suction tube to vacuum middle back area of half carcass.

94. Armpit Washer: Uses high-pressure hose to clean armpit area of half-carcasses as they emerge from wash cabinet.

95. Bone Crusher: Uses hydraulically operated clamp machine to exert pressure on the ribs of half-carcasses, speeding cooling in the cooler.

96. Internal Fat Cutter: Uses hand knife to cut any remaining membranes or fat inside half-sides and score them with “X”.

97. Thirty-Month Cattle Tagger/Recorder/Trimmer: Places bright pink tags with number “30” on all thirty-month cattle to allow for easy identification by cooler workers. Records carcass number of each thirty-month cow to match against dentition assistant’s records.

98. Railer: Works in cooler and uses hooks to organize incoming half-carcasses for overnight chilling.

99. Liver Hanger: Uses hands to take livers off liver line and hang on wheeled carts for chilling.

100. Liver Packer: Uses hands to take chilled livers off racks, wrap them inside plastic bags, pack them two to a box, and stack them on pallets to be shipped or stored.

101: Tongue Washer and Packer: Places tongues into circular metal washer and activates washer. After washing, wraps each tongue in shrink-wrap, boxes it, and places box and offal conveyor.

102. Offal Packer: Uses hands to take hearts, weasands, and tails off offal-line hooks. Tails are thrown into movable cart to be picked up by tail washer and packer. Weasands and hearts are thrown into separate boxes, places on scales to be weighed, then boxed and put on offal conveyor belt.

103. Tail Washer and Packer: Pushes tail cart from offal packer to tail-washing machine. Places tails in tail washer then packer to tail-washing machine. Places tails in tail washer then removes them, boxes them, and puts box on offal conveyor.

104. Intestine and Paunch Separator: Uses hand hook to push paunches down slide to paunch-opening room and intestines onto intestine conveyor. Spreads intestines so that they can be cleaned by water spray.

105. Paunch Opener: Uses hand knife to cut open stomachs and empty them of their partially digested contents. Pushes ingesta down chute, and hangs opened stomachs between two hooks on paunch line for transport to paunch-wash cabinet.

106. Paunch Trimmer: Uses hand knife to trim paunches after they have been washed in paunch-wash cabinet and puts them in circular vat washers to be washed again.

107. Paunch Bandsaw Operator: Uses bandsaw to cut open circular membranes about the size of a volleyball, then places the membranes on conveyor leading to large metallic circular vat to be washed.

108. Primary Intestine Washer: Uses hands to remove large intestines from conveyor, thread them around coils located inside metal boxes, and activate coils, which release water to flush out large intestines. Once they are washed, removed intestines and places them in bin for secondary intestines washer.

109. Secondary Intestine Washer: Uses hands to pick up intestines from bin and thread them onto horizontal flusher. Activates flusher then removes intestines and puts them down slide to offal-packing room.

110: Intestine Trimmer and Packer: Trims intestines for any remaining fecal material and packs intestines in boxes. Places boxes on offal conveyor.

111: Omasum and Tripe Washer and Refiner: Uses hands to operate circular metal tripe and omasum washing vats.

112: Omasum, Tripe, and Honeycomb Packer: Uses hands and hand knife to pack boxes of washed and refined omasum, tripe, and honeycomb and place boxes on offal conveyor.

113. Foot Cooker: Uses hands to operate foot-cooking machines, which operate in spinning motion.

114: Toenail Clipper: Uses hands to stick each cooked foot into machine that operates by two serrated rollers. The rollers, activated by foot lever, spin together and break off “toenail,” or tip of hoof, of each cow foot.

115: Tendon Cutter: Uses hands to push cow feet through band saw to cut off tendons on each foot. Tosses cut feet onto foot table.

116. Foot Trimmer: Uses hand knife to trim each foot of fat and discoloration.

117. Foot Washer and Packer: Sprays water on cow feet, packs six to a box, and places box on offal conveyor.

118. Offal Packer: Uses hands to pull boxes off conveyor, weigh them, print out sticker for each box, put sticker on box, activate machine that places plastic strap around the box, and put box back on conveyor. Opens boxes of hearts, head meat, and cheek meat, and puts one scoop of dry ice into each box.

119: Supply-Room Staff: Controls distribution of equipment to workers, including hairnets, gloves, safety gloves, aprons, knives, rubber bands, plastic bangs, and hard hats.

120. Kill Floor Sanitation Staff: Cleans kill floor throughout the day. Squeegees blood, dumps disposable meat and parts down discard chutes, takes pet-food parts to pet-food chute, and rinses down foam buildup.

121. Nonproduction Sanitation and Laundry Staff: Maintains bathroom and lunchroom and offices. Does laundry.

Image

.

Image

.

Image

REFERENCES (RECOMMENDATIONS)

- Mander, Jerry. Four Arguments for the Elimination of Television. New York: Quill, 1978. Print.

- Postman, Neil. Amusing Ourselves to Death: Public Discourse in the Age of Show Business. New York: Penguin Books, 1986.

- Barrett, Deirdre. Supernormal Stimuli: How Primal Urges Overran Their Evolutionary Purpose. New York: W.W. Norton & Co, 2010. Print.

- Bridle, James. New Dark Age : Technology, Knowledge and the End of the Future. Verso Books, 2018.

- Berger, John. Ways of seeing. Penguin Classics, 2008.

- Brower, Matthew. Developing Animals: Wildlife and Early American Photography. 2010

- Pachirat, Timothy. Every Twelve Seconds: Industrialized Slaughter and the Politics of Sight. 2015

- Monson, Shaun, Persia White, Moby, Maggie Q, and Joaquin Phoenix. Earthlings. Burbank, CA: Earthlings.com, 2010.

- Palfrey, J., & Gasser, U. Born Digital: Understanding the First Generation of Digital Natives, NY, basic books, 2016.

- Shepard, Paul. The Others: How Animals Made Us Human, 1996.

- Baker, Steve. Picturing the Beast: Animals, Identity, and Representation. Reprint, University of Illinois Press, 2001.

- Rothfels, Nigel. Representing Animals. Illustrated, Indiana University Press, 2002.

ACKNOWLEDGMENTS

I would like to give special thanks to my thesis committee: Steve Smith, Anne West, and Nigel Rothfels for all of their guidance and support. To Daniel S. Sanchez, my everything ♡

Thank you to Brian Ulrich, Alex Strada, Stanley Woluka-Wanambwa, Odette England, Nancy Friese, Foad Torshizi, Jennifer Liese, Serge Shea, Paul Sproll, Betsy Sara Ruppa, Benedict Gagliardi, Georgia Rhodes, Dora Mugerwa, Henry Horenstein, Shona Kitchen, Alyson Ogasian, Stephen Cooke, Edek Sher, Renee Hobbs, Maralie Armstrong, Jessica Brown, and Thomas Doran.

To the artists I met along the way, Paul Pfeiffer, Lucas Blalock, Joshua Citarella, Aida Muluneh, Erin Shirreff, Stephanie Deumer, Thomas Lax, and Paul Graham.

To Leah Zhang, Mei Mei, Thomas Wilder, Jessina Leonard, Zihan Iris Li, Thomas Brett, Sabrina, Beth Johnston, Jonathan Jackson, Allie Tsubota, Drew Leventhal, Ali Newhard, Yunwei Zhou, Megan Christiansen, Chance Deville, Hannah Garrett, Ollie Rosario, Danni Xu, Yingheng Huang, Hannah Lutz Winkler, Gregory Deddo, Camilla Jerome, Alexandra Ionescu, Han Seok You, Charlott Isobel Dazan, Keavy Handley-Byrne, Lily Colman, Erik Guzman, Amber Mahoney, Ndivhuho Rasengani, Kevin Hubbard, Cem Eskinazi, Carl-Gustaf Ewerbring, Ethan Murakami, Kasia Hope, Jesse Burke, Janie Kowalchuk, Gregory Shark, Alana Perino, Niko Krivanek, Emily Bright, Kelvin Lopez, the nature lab, fleet library, center for arts & language, mailroom and fletcher building staff, and anyone else I crossed paths with that made this moment of time that much more memorable.